We've been walking for 60 years.

It was a very long and lonely road.

We've been walking for 60 years.

It was a very long and lonely road.

the power to make change possible,

It begins with an idea that goes beyond definition.

Along with Youngdo Velvet's 60-year history, velvet has changed our lives by constantly changing into a high-tech material beyond fashion.

We will build a technological foundation for sustainable growth as a 100-year-old company by investing heavily in creative research and development in new technologies, new product development and product, and process innovation.

Youngdo Velvet Central Research Center was established as a corporate affiliated research center in 2005 in recognition of technology accumulated over 60 years, trained professional manpower, and advanced test facilities.

The innovative power of Velvet is the ability to see the future of the talents of the central research institute that promoted technology development with water-washable velvet, LCD rubbing cloth, and high-tech materials for electric vehicles.

Based on this, it has been recognized worldwide as a venture company, InnoBIZ (technologically innovative company), and material part equipment specialized company, and cotton velvet and poly velvet produced by Youngdo Velvet have been selected as world-class products from the Korean government.

Youngdo Velvet Central Research Institute will take the lead in the constant innovation and change of a single item of velvet and lead the change in the lives of people around the world.

For 800 years before the 20th century, velvet, which was recognized as the finest fiber for its beautiful luster and soft touch, suffered damage to the fabric when leaning or sitting on it.

Youngdo Velvet strived to improve these shortcomings and develop new products tailored to the lifestyle of consumers that require practicality. One day, Youngdo noticed that the crease lines of suit pants became angular when ironed, so I grafted the thermoplasticity of synthetic fiber principle into the fabric, and this is micro-velvet that can withstand any harsh environment. Micro Velvet, a water-washable velvet developed in 2000, the first year of the 21st century, opened a new path in the velvet product market, and it took 12 years for Chinese competitors to copy and follow.

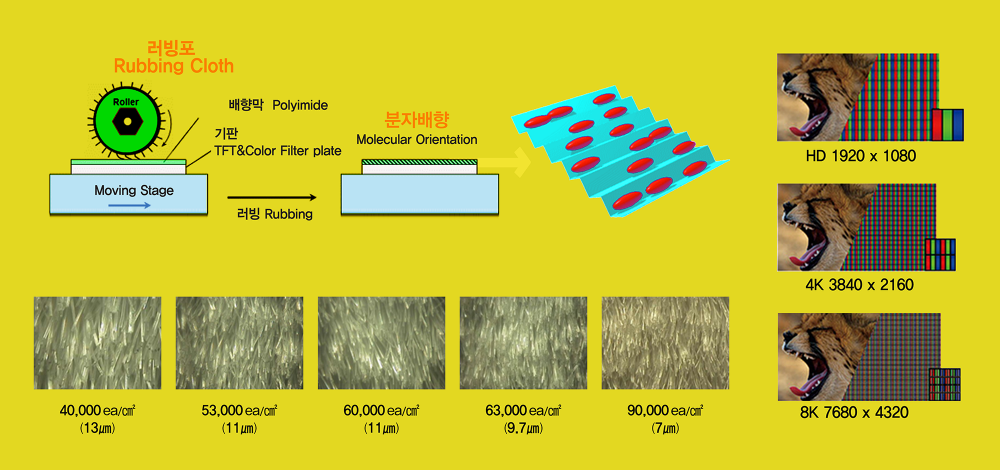

LCD rubbing cloth is a material necessary for the process of realigning the alignment layer molecules by mechanically rubbing the thin film coated on the substrate for the purpose of arranging the liquid crystal molecules in a certain direction. The quality of rubbing cloth for LCD panel manufacturing is the most important factor that affects the reliability and productivity of the rubbing process, and thus affects the yield of the LCD panel process.

Youngdo Velvet started research in the 2000s when the LCD panel industry was growing rapidly, when Japanese monopolists exclusively controlled supply, and succeeded in localization in 2008. Contributed to industrial advancement and growth.

Youngdo Velvet's Rubbing Cloth products have a high pile density and small pile length variation and brushing angle variation, making them an essential component material for the production of some items for ultra-high-definition TV and mobile products. The <Retina Display> of Apple's iPad is a representative example. This can be said to be the result of the tireless efforts of the R&D team of Youngdo Velvet for many years.

In the high-tech material industry, Youngdo Velvet's core competency is velvet weaving technology with a three-dimensional multi-layer structure with a large specific surface area, which represents the surface area per unit mass of particles. While general high-tech materials improve performance through the process of layering materials with a flat structure, velvet weave replaces this process with the length of pile, density and angle between piles. As a result, the space between the piles provides a large specific surface area to improve the mechanical and electrical properties of the material, the length and height of the piles provide process simplification and cost reduction by omitting the lamination process, and the multi-layer structure containing air has a non-elasticity It is high and the deformation is small even with strong impact.

Youngdo Velvet is (1) high-tech environmental materials such as fine dust adsorption velvet and heavy metal filtration velvet (2) high-tech materials for electric and electronic applications such as battery electrode materials and flat panel display electrical emission materials, (3) composite reinforcement materials such as elastic steel sheet velvet and bulletproof velvet We are developing advanced materials in three business directions, and aiming to commercialize them by 2030.

Based on this, yesterday's No. 1 textile company will leap forward to become a high-tech material company today.

Distributor information

Distributor information

We will head for new experiences

while maintaining the pride of Velvet.

CONTACT

CONTACT

COPYRIGHT ⓒ 2022 YOUNGDO VELVET.

ALL RIGHTS RESERVED.

CONTACT US