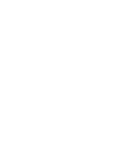

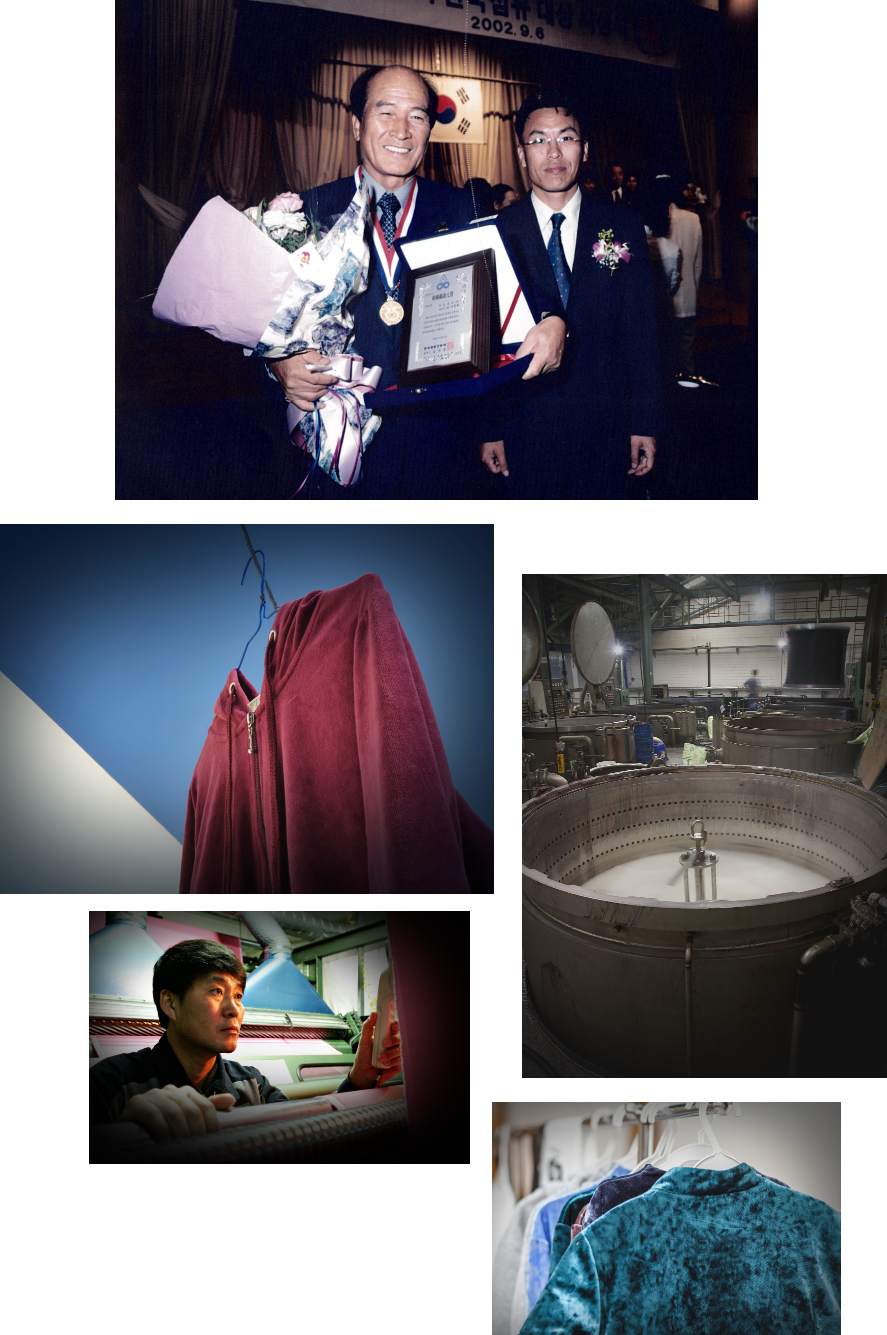

Acetate velvet (called double velvet), which was popular in the 70s and 80s, was popular for its beautiful luster and soft touch.

However, due to the disadvantage of lying down and damaging the pile when leaning or sitting, consumers said, 'You have to carry velvet clothes'.

Moreover, due to the trend of practicality and casual wear that has been blowing since the 1990s, consumers have preferred more active and easy-to-manage materials, and the velvet industry has shrunk.

One day in the early 1990s, Chairman Lee Won-hwa, who saw that the wrinkles of suit pants were angular due to ironing, tried to develop a velvet that could withstand any harsh environment by using 'thermoplasticity of synthetic fibers'.

Together with Lee Seong-yeol, the factory manager in charge of the production line at the time, he designed his own high-pressure dyeing machine, which is essential for polyester processing, and manufactured it by gathering scrap steel parts from a tool alley in Bukseong-ro, Daegu.

And as a result of repeating the washing experiment by making clothes with the first 7 yards of the sample, it was confirmed that the pile would not be damaged even when washed with water.

However, in the process of 'reduction processing', which softens stiff polyester fibers, a problem occurred that the fabric was torn.

One day on a business trip to Osaka, Japan, he saw that the durability of the silket fabric he had purchased was excellent, and he was able to solve the problem of wear and tear by changing the existing design method.

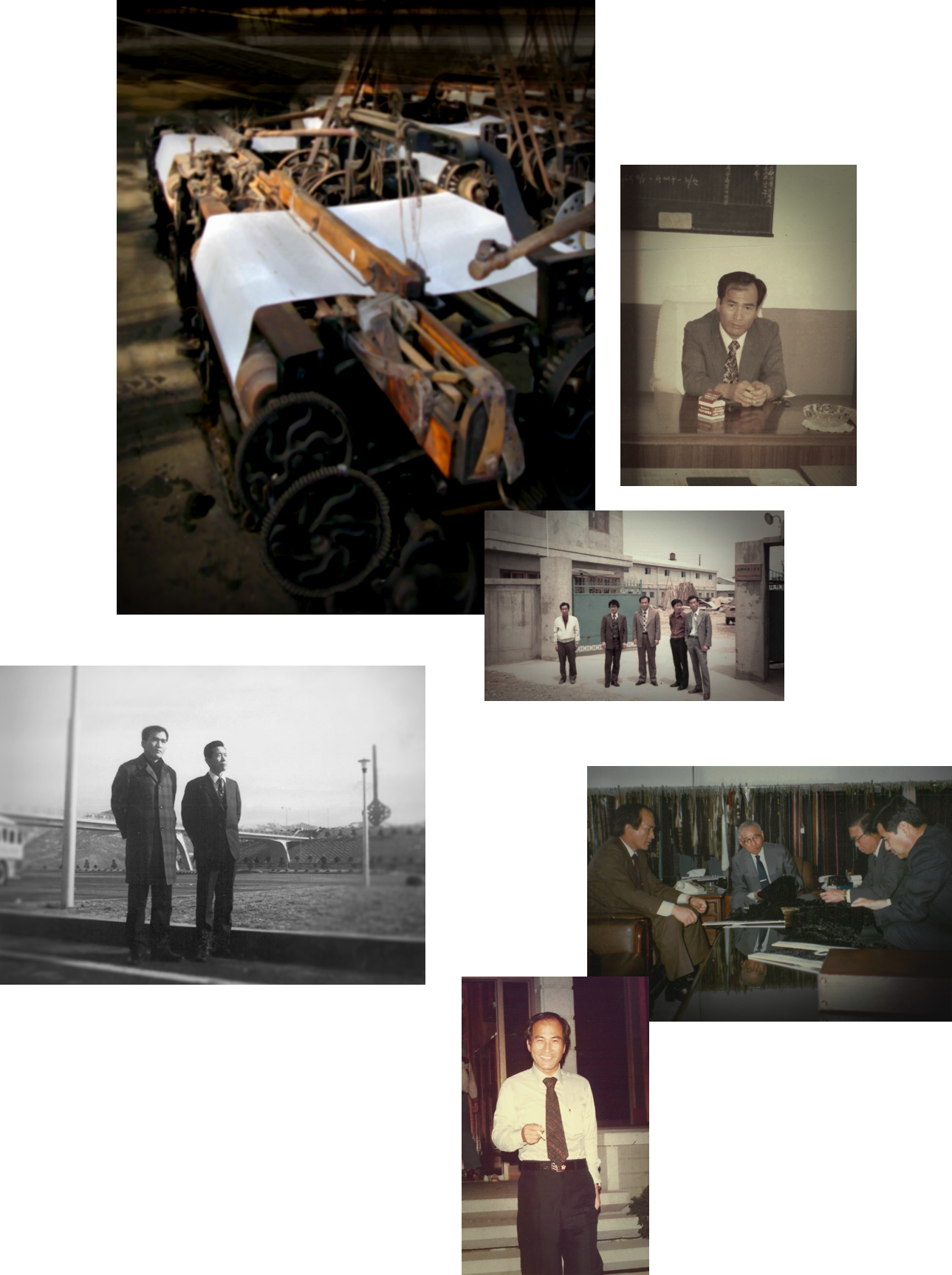

Micro velvet is the main character that made 'Youngdo' leap forward as a high-tech material company, and it is an innovative product in the global velvet industry and was selected as a world-class product.

It took 12 years for China to imitate the quality of Youngdo Micro Velvet.

Distributor information

Distributor information

CONTACT

CONTACT